PRODUCT CENTER

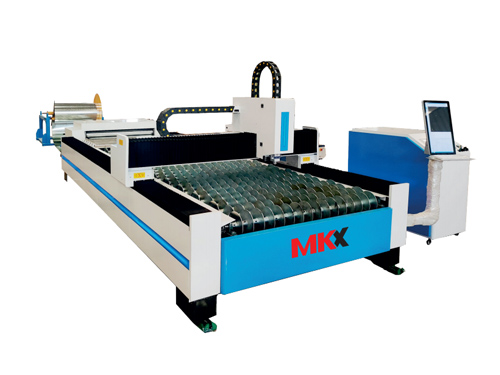

MKX DUCT MANUFACTURE AUTO-LINE

Basic configuration

1. One electric feeder frame (two trays)

2. One set of reinforcement leveling device 3. Four sets of hydraulic Angle cutting machine with mold and hydraulic punching

2 sets of hole mold, 1 set of support hole mold

4. Hydraulic shearing machine

5. Computer and controller and production software

The second line of Meikasai air duct production is composed of loading frame, leveling and pressing machine, punching tip and punching square machine, common plate side hole, support hole die, hydraulic shearing machine. The electrical control part is controlled by computer. The control system has a closed-loop feedback system, and the production precision and stability are obviously improved. Its working speed is 14 m/ min, the length error is ±0.5mm/m, the diagonal error is ±0.8mm/m, galvanized sheet 0.5-2.0mm, stainless steel 0... 5-1.2mm.

Working principle

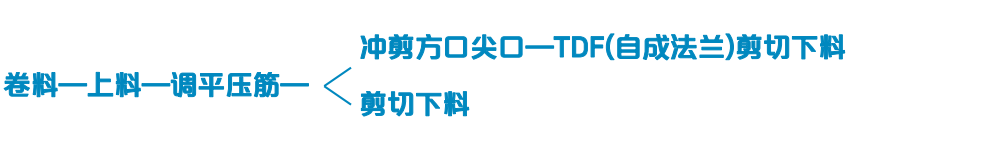

Work diagram

电话

电话 地图

地图